Our first building block

Arteron IM-1: Immediate Deployment Water Treatment System

We are now able to scale it’s inherent treatment process up and down in capacity and adapt it to different raw water sources.

In the context of distributed water infrastructure this is one in a range of different treatment technologies that we design and employ, where each of these ultra compact systems serve as fundamental building blocks in a remotely managed water network.

Capital efficiency

“Distributed infrastructure lowers capital demand. From the perspective of capital deployment it just makes sense.”

Distributed infrastructure is actually cheaper by easily up to 40% as compared to centralised infrastructure. Capital is also used more efficiently as you can roll out progressively and quickly. As each plant becomes operational (usually in a matter of weeks from fabrication to operation) it immediately begins generating revenue, unlike in the centralised model where the construction cycle is longer, often measured in years instead of weeks and no revenue can be generated until the plant and piping is operational.

Risk is also greatly mitigated, contained within the deployment and operation of each micro plant. This is further mitigated by the design of the plants which allow for the plant to be dismantled and moved to another site should the need arise, thereby protecting the asset.

Rural Scenarios

A hard to access location, it is devoid of basic amenities such as power and clean water. The unit with a capacity of 35,000 litres/day provides clean drinking water for all the consumption needs of the school of approximately 300 students and teachers.

Salung is a small village in the district of Pensiangan. About six hours drive from Kota Kinabalu. The route there passes through Keningau town, Sook and Sapulut and several small villages before arriving at the jetty for the boat ride to Salung.

RS-1: In Action

It is a lightweight potable water treatment system producing an treated output capacity of 35,000 litres a day designed specifically for rural development areas, where access to placing a system can be challenging. The example shown in the photos illustrates our system deployed in a deep rural Sabah location, where the difficulty of transporting a system over a narrow wooden suspension bridge across a river to a rural school of 300 students is overcome. This would not be possible with competing alternatives of the same treatment capacity. The RS-1 system weighs 220kg and it is the smallest system in the category of rural support systems we offer.

ED-1: State of the Art

Now in its 4th generation, the evolution of our original IM-1 system, now dubbed the ED-1 (for Emergency Development) our current model represents years of optimisations and advancements on our original design. It is a better performer in every respect. A perfect choice for first responder emergency response teams, it is perfect for air logistics with unsurpassed performance, reliability and simplicity in operation and maintenance.

The Arteron ED-1 is a feature-packed Water Filtration System that is highly mobile and is designed for use in the most demanding situations and environments. The ED-1 weighs approximately 167kg and comes transport-ready in a rugged, medium-sized trunk and is ideal for use in small communities and for emergency advance teams.

Despite its size the ED-1 sacrifices none of the functionality of its larger sibling and shares much of the same underlying technology. Developed to meet the needs of crisis management professionals the ED-1 is a rugged, instant deployment water filtration unit that can meet the water requirement needs of up to 700 people, providing as much as 35,000 litres of clean potable water per day.

Its small footprint makes it the ideal solution to turn almost any available water source – from river water to wells to contaminated mains supplies – into potable water for the surrounding community.

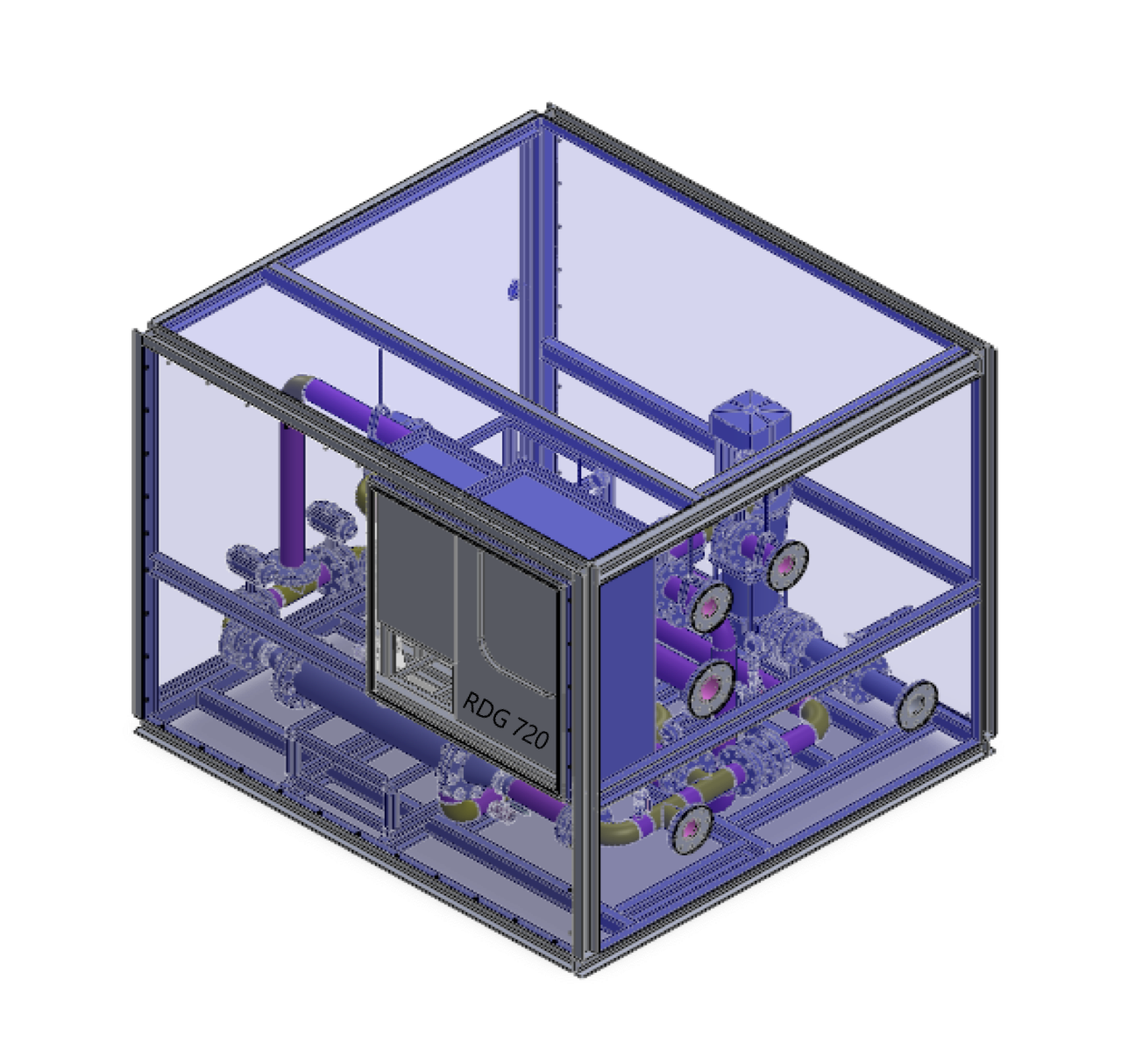

RDG 720: System & Process

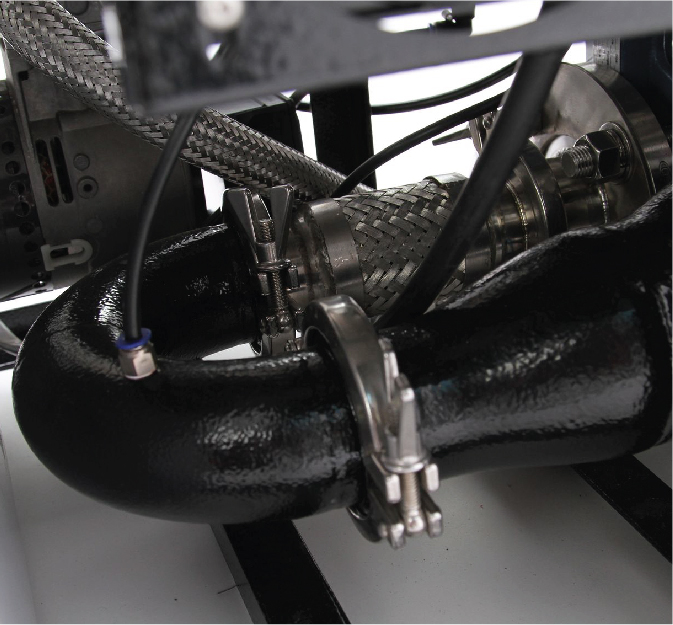

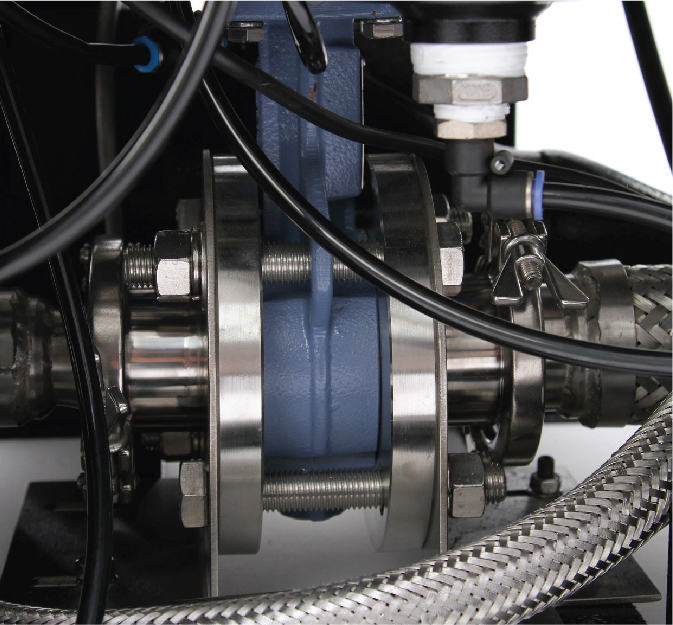

The RDG 720 Water Filtration System is a larger scale adaptation of our flagship IM-1. It is very similar in its applications and functions but larger in capacity and output to the IM-1.

It is built in a modular and flexible configuration and is well suited to tough environmental conditions.

It is also designed to be set in place permanently while still retaining the ability to be dismantled and moved easily should the need arise and is ideal for remote or inaccessible locations or as a water treatment solution for rural communities with poor quality water sources.

Final Production Design

In House Development and Testing Unit

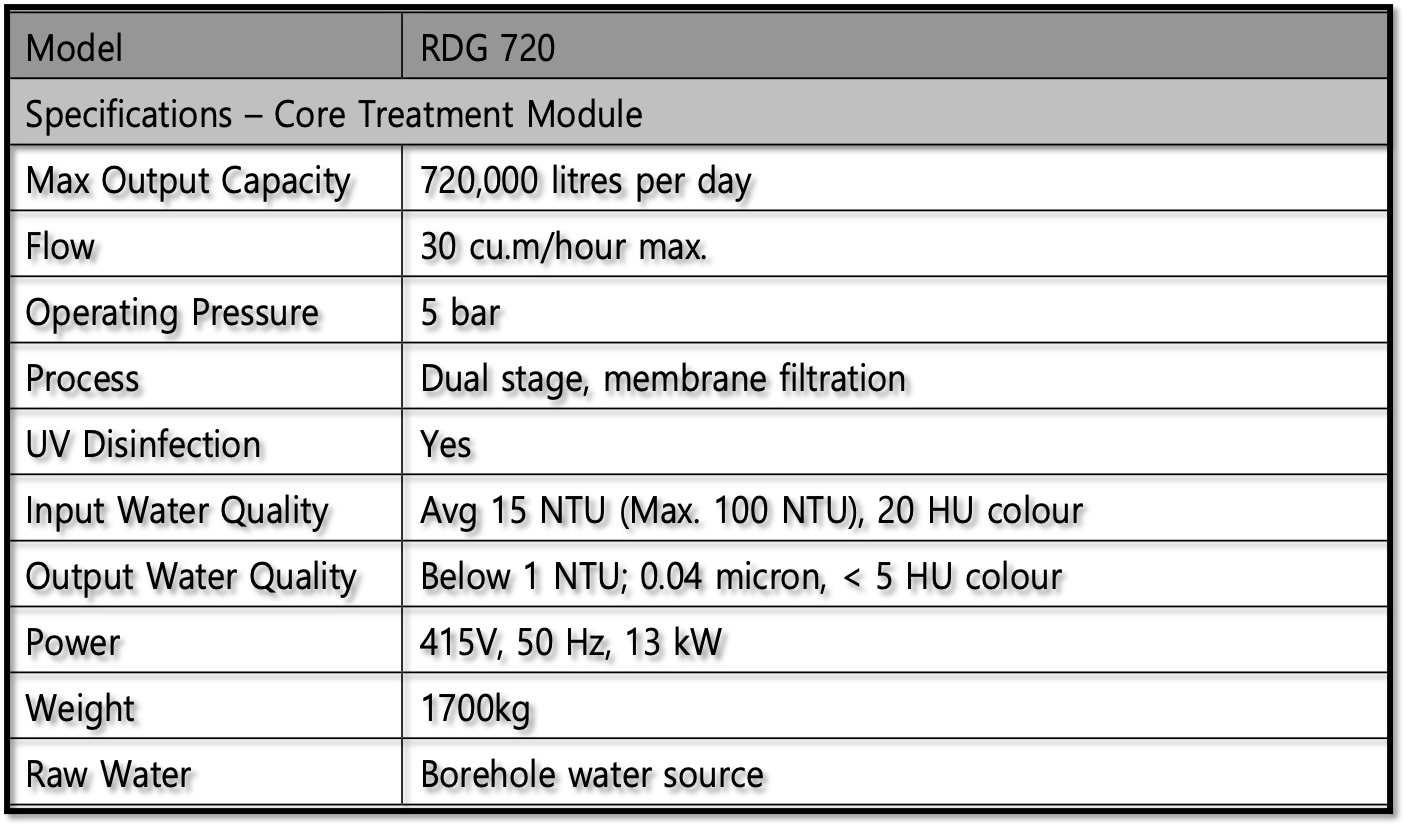

RDG 720 Product Specification

© 2018 Arteron Global Systems Pte Ltd. All Rights Reserved.