Decentralisation

Background

Centralised infrastructure – not ideal for all

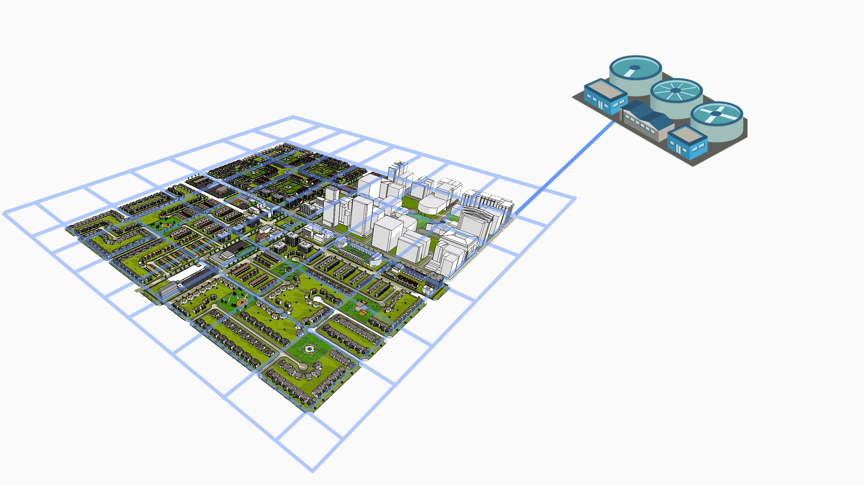

Figure 1. Western communities often planned in grid format, making it easy to install piping infrastructure.

Traditional thinking in water treatment involves large centralised plants & industrial piping. This approach works well in highly populated areas, but unfortunately does not adapt very well to the scenarios faced by developing nations.

Figure 2. Exaggerated but descriptive illustration of how piping infrastructure layout may look like in developing countries.

In many developing countries, development has occurred organically over the last 50 or so years at an extremely rapid pace, often in a very disorganised way. Frequently water infrastructure is considered and installed after the fact, at which point it can be a very challenging and often prohibitively expensive affair, as many obstacles have to be contended with.

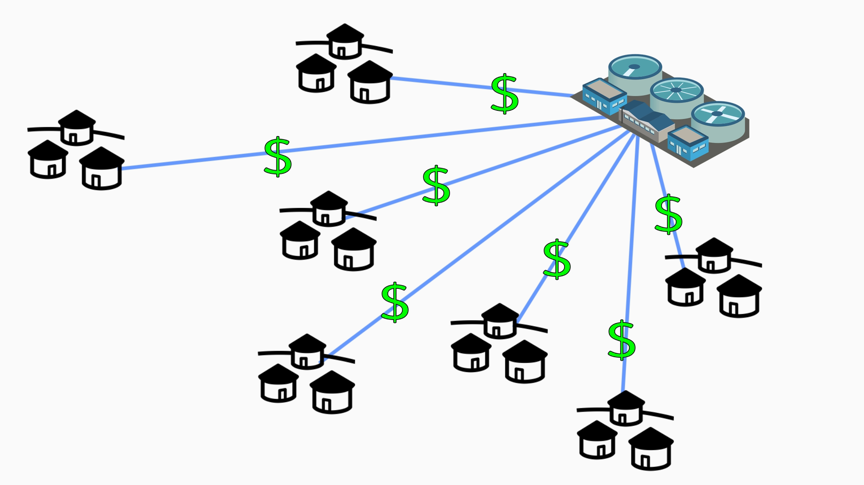

Figure 3. The primary cost is in piping infrastructure.

Outside of the urban environment communities are often small and spread out. Serving these small communities with this approach is hard to do due to the high cost involved.

With centralised infrastructure the numbers just don’t add up for serving smaller populations.

It doesn’t make much financial sense to run large piping systems long distances just to serve small groups of people, so these communities tend to get left behind.

Apart from the cost of the treatment plant, piping distribution systems alone can cost 4-5 times the cost of a centralised treatment plant.

Making matters worse, younger generations have been migrating to cities, chasing opportunity and better living standards. As a result rural communities are being left behind.

Distributed Water Network

- Pre designed compact systems will form the basic building blocks in a distributed water infrastructure network.

- Each system is an intelligent “cell” in that network.

- These “cells” can be remotely managed; where each water system hooks into the network to be remotely managed from central command centres, increasing safety, reliability and streamlining logistics.

The network will be managed as a single entity:

- Reduces manpower cost

- Reduces risk of human error

- Optimises reliability

- Simplifies maintenance

- Reduces load on the environment by geographically distributing load on raw water use

Data from each “cell” can be consolidated in real time:

- Cloud based dashboard

- Enabling data collation

- Accounting

- Operations monitoring

As each system is “smart”, distributed infrastructure also creates unprecedented opportunities for gathering data on all sorts of things:

- Hydrology

- Consumption patterns

- Weather

- Etc.

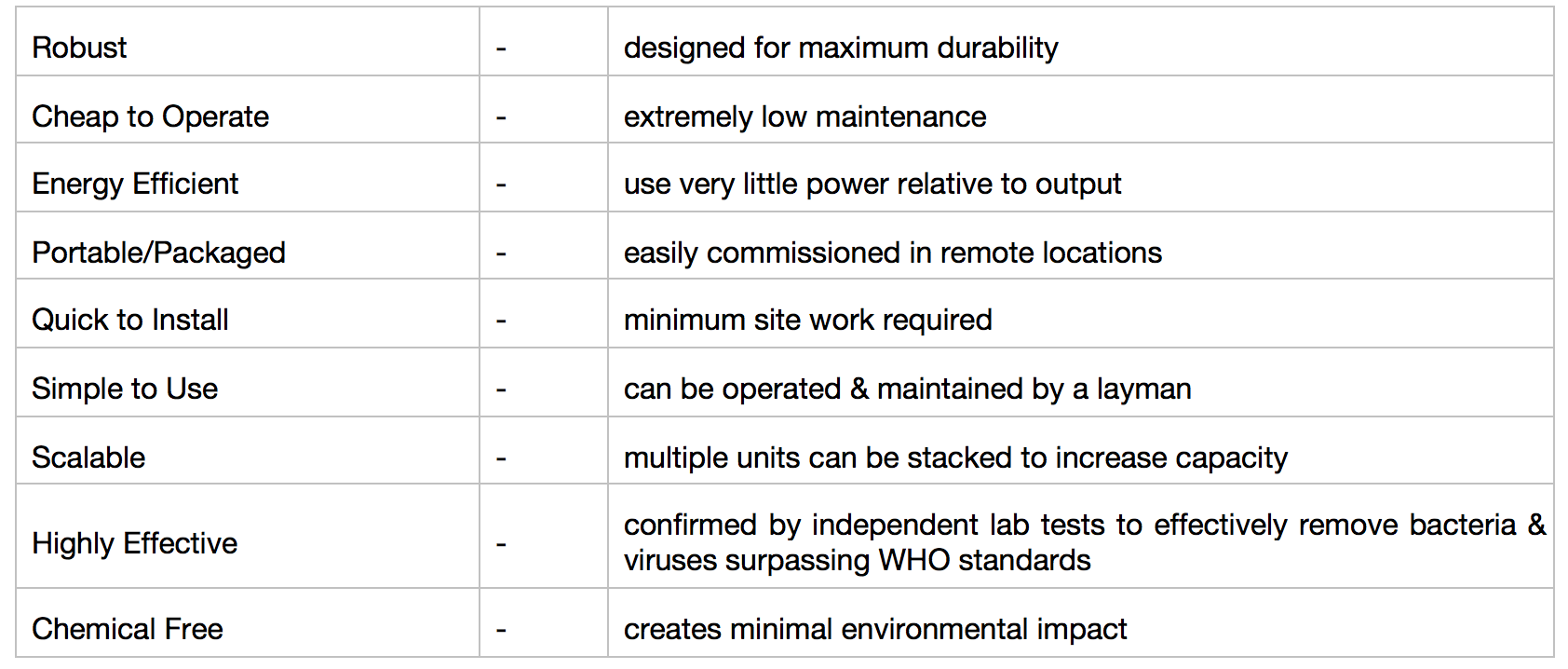

Guiding Principles

All our solutions are designed according to a set of driving criteria. The must be:

Scaling Up

What are some of the key technical factors for successful decentralisation?

While decentralisation may be a great idea in theory, there are always pros and cons with any approach. One of the good things about centralized treatment plants is that if you have a problem, you have it one place. With decentralization however, if there is an inherent technical flaw then you will have that problem in many places.

Key criteria for successful decentralisation:

- Simple operation

Technical knowledge should not be required to operate a system. Operation should not be any more complicated than operating a TV remote. The operator should not require more than an hour of training to operate and maintain the system. All complex processes should be automated “under the hood” so to speak.

- Easy maintenance

Simple and cheap maintenance is the key to easy management when deploying at a larger scale. Maintenance should be simple enough to be performed by the end user with the bare minimum of training.

- Energy efficiency

As electricity is also usually a problem in rural environments, filtration systems need to produce the maximum amount of treated water while using the minimum amount of energy to do it. Our solutions run at very low pressures, therefore requiring very little energy relative to output volume.

- Reliability

Simplicity is the key to reliability. The treatment process should be confined to as few stages as possible to reduce the number of components involved. Electrical and other moving parts should be kept to a minimum. Recent advancements in filtration technology have helped us design extremely reliable processes that are chemical free in the majority of cases.

Dependency on commonly used industrial chemicals such as caustic soda and industrial acids create handling and safety concerns, especially when you take into account that the end user may not be well trained or educated, raising the risk of injury or even death in the worst case.

Reliance on proprietary components or chemicals should be minimized or eliminated as supply issues can cause downtime and make maintenance complicated and more costly.

- Robustness

Given the conditions they can be placed in, this equipment needs to be robust. We do not use fragile treatment processes that require close operational supervision. Any machine, regardless of how well intended the design may be, will break down at some point.

It is therefore essential to have a built in strategy for efficient repairs and servicing. Repairs should be carried out as easily as possible and equipment should never require a return to the factory. For example, we colour code indicator lights that illuminate to indicate failure in any part of the system.

We have found from experience that even in the most rural of environments hand phones are widely used, not only for communication but also for trading and ordering. Text messaging is the lowest common denominator in terms of communication.

So if other means are not available, the user only has to notify a technician via text message of the name and colour of the light and the technician can be dispatched with the right parts for the job.

- Easy management when deployed at large scale

As mentioned we are ultimately designing distributed water networks. These networks would be made up of many cells, each cell being a single treatment system. With robust design, telemetry and data capabilities, energy efficiency and reduced dependency on chemical consumables these systems are easily managed even when in large numbers.

- Rapidly manufactured and installed

By pre designing systems with wide ranging capabilities we are moving away from the traditional consultative approach of the water treatment industry. The consultative approach results primarily in bespoke treatment systems and operations, making the delivery process slow, costly and therefore difficult to scale. With standardised, modular system designs it is much easier to rapidly produce and install systems.

Where it would normally take several months for a treatment plant to go from design to operation, a decentralised system can be built in 2 weeks and installed, tested and commissioned in an additional 2 weeks, making a grand total of 1 month for it to go from fabrication to fully operational.

© 2018 Arteron Global Systems Pte Ltd. All Rights Reserved.